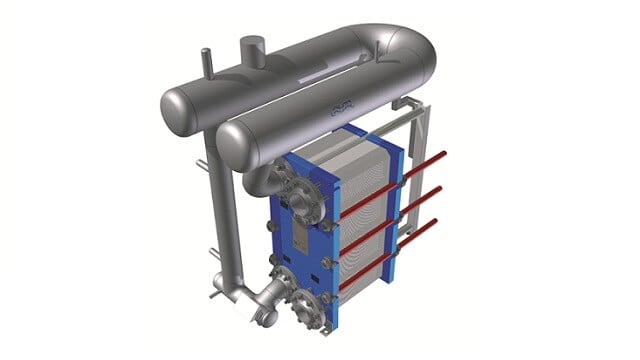

U-Turn

U-Turn is a liquid separator especially designed for use with plate heat exchangers in ammonia applications. The module – including the separator and plate heat exchanger ensures minimum pressure drop losses and maximum energy efficiency.

Alfa Laval U-Turn is designed to utilize the very best from Alfa Laval’s plate heat exchanger technology. Installed above, the self-contained U-Turn can be easily mounted onto the compatible plate heat exchanger. It can cover ammonia capacities from 200 to 1400 kW at 0°C evaporation temperature and from 50 to 500 kW at -40°C evaporation temperature.

The module provides an effective and compact installation with less vertical rise and smaller overall dimensions than any other solution.

Main design features

- Compact dimensions

- Shorter height and length allowing installation onsite without dismantling

- No additional support is needed, as the U-Turn separator is supported entirely by the plate heat exchanger

- Easy maintenance, as both sides of the plate heat exchanger are fully accessible.

- All ammonia connections access the same side which makes installation easy

- Integrated oil drain

- Stainless steel ensuring corrosion resistance and no need of surface treatment

Ready to install

The U-Turn module is delivered within short time, due to standardization. It is a fully functional module from one supplier and carries the CE-stamp, as well the approval from PED (Pressure Equipment Directive).

Come funziona:

- It ensures efficient separation – due to the use of four different

separation methods. - The short vertical ammonia driving columns, allowing small

temperature approaches and high system efficiency. - Sliding support allows thermal expansion, ensuring no

thermal tensions build up. - Significant oil pot volume in standard execution enough

for manual drain - Separation based on droplet size 0.15 mm

- Margin for separation is 25% plus one nominal diameter

- Maximum separation gas velocity is restricted to 60% of

the re-entrainment velocity, avoiding liquid brought back

to the gas flow. - Extra safety margin from 180° U-bend.

Ready to install

The U-Turn module is delivered within short time, due to standardization. It is a fully functional module from one supplier and carries the CE-stamp, as well the approval from PED (Pressure Equipment Directive).