La centrifuga decanter Alfa Laval riduce le perdite chimiche nei residui di liquore verde

Södra Cell è uno dei principali produttori mondiali di polpa di cellulosa per il mercato. La produzione di polpa di cellulosa dell’azienda avviene in tre stabilimenti in Svezia e due in Norvegia, con un volume di produzione annuale totale che supera i 2 milioni di tonnellate.

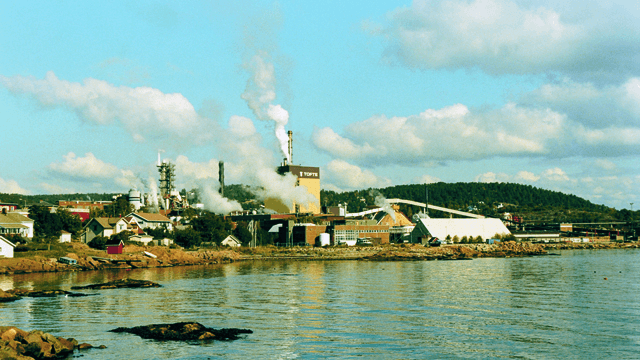

DATA 2026-02-04Lo stabilimento Södra Cell di Tofte, situato ai margini del fiordo di Oslo, produce circa 400.000 tonnellate all’anno di polpa solfata ECF da una miscela di legno tenero e legno duro (eucalipto).

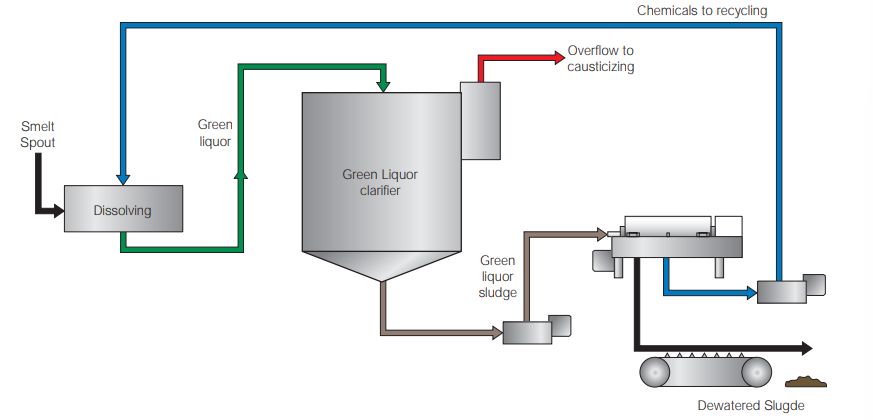

Come parte del sistema di recupero chimico, l’impianto utilizzava un filtro a vuoto per la disidratazione dei residui di liquore verde dopo il chiarificatore. Il filtro a vuoto esistente era limitato in capacità e forniva una secchezza della torta molto bassa, non superiore al 40%.

“Questo significava un recupero chimico scarso e grandi difficoltà nella gestione dei fanghi per lo smaltimento,”

-Solveig Borge Tveit, responsabile del reparto di recupero chimico

Test comparativo

Nel 2003, un test comparativo ha mostrato che una centrifuga decanter era più adatta per la disidratazione rispetto ai filtri a vuoto con precoat. In quel momento, la secchezza della torta è stata misurata vicino al 55% di sostanza secca.

I vantaggi dell’utilizzo di una centrifuga decanter si sono rivelati numerosi:

- Costi di installazione inferiori

- Maggiore recupero chimico

- Migliore capacità di gestione dei fanghi

- Costi di smaltimento dei fanghi più bassi

Oltre le aspettative

Nel luglio 2004, una centrifuga decanter Alfa Laval è stata messa in funzione per trattare l’intero volume di residui di liquore verde prodotti da Södra Cell Tofte. “Le prestazioni della macchina hanno effettivamente superato le previsioni, con una secchezza della torta costantemente superiore al 60%. Questo si traduce in un recupero chimico molto migliore e in risparmi che coprono ampiamente il costo dei polimeri aggiunti per ottenere una corretta chiarificazione del troppo pieno,” afferma Solveig Borge Tveit. Anche quando la cartiera funziona a piena capacità, la centrifuga decanter deve funzionare solo 5 giorni a settimana e quindi ha ancora capacità residua.

Bassi costi operativi

La centrifuga decanter Alfa Laval non richiede azioni specifiche da parte degli operatori, come il pre-coating. Dopo ogni ciclo, la macchina necessita solo di un lavaggio con acqua calda, condensa o qualsiasi altro flusso caldo disponibile. Questo nuovo tipo di centrifuga si è anche dimostrato molto basso in termini di consumo energetico.

Installazione semplice

“Ci sono voluti solo 14 giorni per rimuovere il filtro a vuoto esistente e sostituirlo con la nuova centrifuga decanter – che occupava solo il 20% dello spazio che sarebbe stato necessario per un nuovo filtro!”

-Pål Salberg, ingegnere di progetto responsabile dell’installazione

Bassi costi di manutenzione

“Dopo 15 mesi e 6.500 ore di funzionamento, non abbiamo ancora dovuto aprire la macchina. Probabilmente seguiremo le raccomandazioni Alfa Laval e pianificheremo una manutenzione standard della macchina dopo le prime 8.000 ore,”

-Pål Salberg.

Questo servizio consiste principalmente nel cambio dei cuscinetti e delle guarnizioni. Prima dell’installazione è stata anche discussa la possibile usura delle pale del trasportatore, tenendo presente che Alfa Laval può fornire anche piastrelle in carburo di tungsteno, che potrebbero essere aggiunte successivamente. Tuttavia, l’azienda ha optato per la superficie di alta qualità Alfa Laval per le pale, e dopo regolari follow-up, Södra Cell Tofte è molto soddisfatta di questa scelta.

Prodotti

Decanter Alfa Laval SG2

La serie completa di decanter per bioetanolo Alfa Laval, progettata e costruita per i produttori di etanolo. SG2 è la scelta dei produttori per la produzione di etanolo.

Vantaggi

- Costi di installazione inferiori

- Maggiore recupero dei prodotti chimici

- Migliore capacità di gestione dei fanghi

- Costi di smaltimento dei fanghi ridotti

Voce del cliente

Dopo 15 mesi e 6.500 ore di funzionamento, non abbiamo ancora dovuto aprire la macchina. Probabilmente seguiremo le raccomandazioni di Alfa Laval e pianificheremo una manutenzione standard della macchina dopo le prime 8.000 ore.

Pål Salberg

Ingegnere di progetto

Benefits

- Lower installation costs

- Higher chemical recovery

- Better ability to handle the sludge

- Lower sludge disposal costs.

Customer's voice

After 15 months and 6,500 hours of operation, we have not yet had to open the machine. We’ll probably follow the Alfa Laval recommendations and plan a standard service of the machine after the first 8,000 hours.

Pål Salberg

Project Engineer