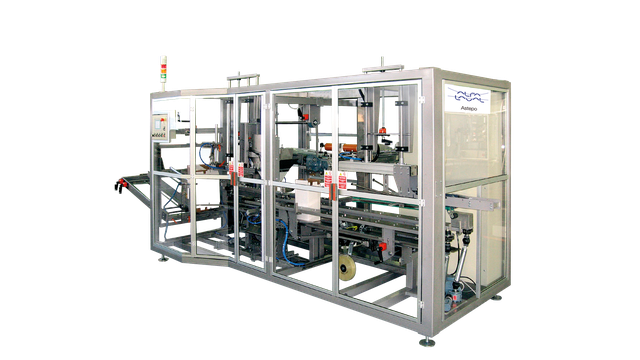

Astepo combibox

Compact cartoning system for the food and beverage industries.

The Combibox system features a space-saving design with three machines in one single frame: the carton box former, carton box inserter/bag loader and the carton box closer.

The movement of the carton box from one phase to another takes place step by step, and the integrated control system simplifies all working and maintenance operations.

The Combibox system can handle both French and American closures, and change-overs from one bag size to another take only a few minutes.

The Combibox system is designed and built in accordance with EC regulations for safety protection. The equipment is made of stainless steel so it can be placed in areas used for food production, and the design allows easy access to all parts for cleaning.

Come funziona:

How it works

The carton box erector automatically opens the box, folds the lower flaps and seals them with adhesive tape or hot glue. A gear motor controls the two principal linear movements of the machine. One of these is for withdrawing and opening the carton box, while the other is for movement during the sealing stage. The carton box flaps are opened and sealed by electro pneumatic movements.

The carton feeding unit is of the step-feed type. The bag cartoner runs on a food-grade tape belt, installed on pneumatic cylinders that move the flaps sideways to make sure the bags fall gently into the carton to avoid friction and twisting.

The integrated control management system makes both operation and maintenance easy. The control panel with pre-installed software is configured to synchronize the working phases with the aseptic and non-aseptic fillers required.