AS-H sequencing batch reactor

L’Alfa Laval ASH Sequencing Batch Reactor (SBR) è una tecnologia biologica avanzata per il trattamento delle acque reflue, progettata per alte prestazioni e massima affidabilità. Utilizzando il processo a fanghi attivi in modalità sequenziale a batch, soddisfa i requisiti di scarico più stringenti e offre un’eccellente flessibilità per comunità e industrie, con portate di decantazione superiori a 25.000 gpm.

Soluzione SBR “all-in-one” per il trattamento delle acque reflue civili e industriali

- Design semplice e robusto: tutti i passaggi del processo biologico avvengono nello stesso serbatoio

- Integra le fasi anaerobica, anossica, aerobica e di sedimentazione in un unico reattore, massimizzando l’efficienza, riducendo l’ingombro e i costi

- Ideale per reflui civili e industriali che richiedono qualità dell’effluente costante anche con portate e carichi variabili

- Ideale per reflui civili e industriali che richiedono qualità dell’effluente costante anche con portate e carichi variabili

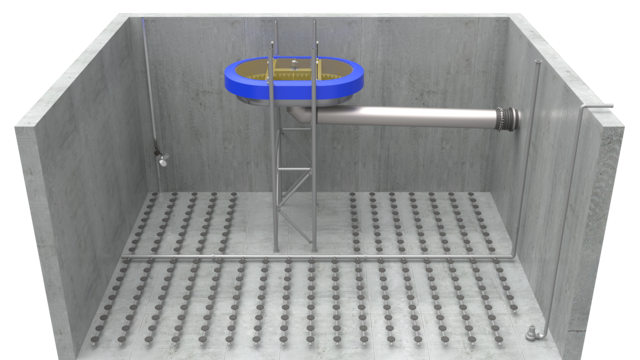

- Facile da inserire in impianti esistenti e lagune in terra, oppure disponibile in configurazione “package plant” preassemblata

Vantaggi del trattamento SBR delle acque reflue con portate e carichi variabili

Il processo a reattore sequenziale a batch (SBR) è adatto al trattamento di tutti i tipi di reflui biodegradabili, rimuovendo BOD (domanda biochimica di ossigeno), COD (domanda chimica di ossigeno), solidi sospesi totali (TSS) e nutrienti chiave come azoto e fosforo. Offre un controllo ottimizzato del processo SBR grazie ad automazione avanzata e grande flessibilità. A differenza dei sistemi convenzionali, questa soluzione SBR integra tutte le funzioni a fanghi attivi in un unico reattore, eliminando la necessità di vasche separate per le fasi anaerobica, anossica, aerobica ciclica e di sedimentazione.

Particolarmente indicata per applicazioni con portata in ingresso e carichi organici variabili e con requisiti di scarico stringenti, questa soluzione “all‑in‑one” a reattori SBR è fornita completa di decantatori flottanti, soffianti, sistema di aerazione diffusa, miscelatori, pompe fanghi di supero, valvole motorizzate di ingresso e di controllo aria, oltre a strumentazione completa e centro di controllo di processo. Progettata per la massima flessibilità, si adatta a numerose geometrie di bacino ed è ideale sia per nuove installazioni sia per il revamping di vasche o lagune esistenti.

Che cos’è il trattamento delle acque reflue con reattore SBR (Sequencing Batch Reactor)?

Il processo SBR per il trattamento delle acque reflue è un tipo di sistema a fanghi attivi utilizzato principalmente negli impianti civili e industriali, che tratta il refluo in batch tramite una serie di cicli regolati automaticamente per ottimizzare il trattamento in base alle reali portate al processo:

- Static Fill – L’acqua reflua entra nel serbatoio senza miscelazione né aerazione.

- React Fill – L’ingresso del refluo continua mentre iniziano aerazione e miscelazione.

- React Phase – Avviene il trattamento biologico: i microrganismi degradano gli inquinanti.

- Settling – L’aerazione si arresta e i solidi sedimentano in condizioni perfettamente quiescenti.

- Decanting – L’acqua chiarificata trattata viene allontanata a portata costante per l’intera durata del ciclo.

- Sludge Wasting – I fanghi in eccesso vengono rimossi dal sistema.

Aerazione e miscelazione sono controllate automaticamente durante i cicli di reazione (React Fill e React Phase) per garantire il raggiungimento della qualità dell’effluente desiderata, incluso l’abbattimento avanzato dei nutrienti, con rimozione mirata di azoto (N) e fosforo (P).

Come funzionano i reattori SBR (Sequencing Batch Reactor)?

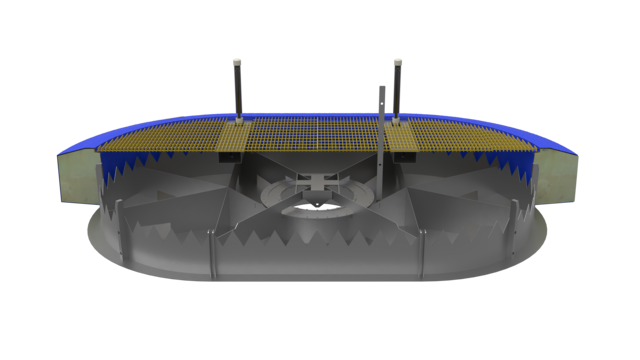

Il reattore SBR Alfa Laval ASH riunisce in un unico reattore automatizzato tutti gli elementi chiave della tecnologia avanzata a fanghi attivi – processi anaerobici, anossici, aerobici ciclici e di sedimentazione – passando in sequenza da una fase all’altra in modo da ottimizzare il tempo dedicato a ciascun passaggio.

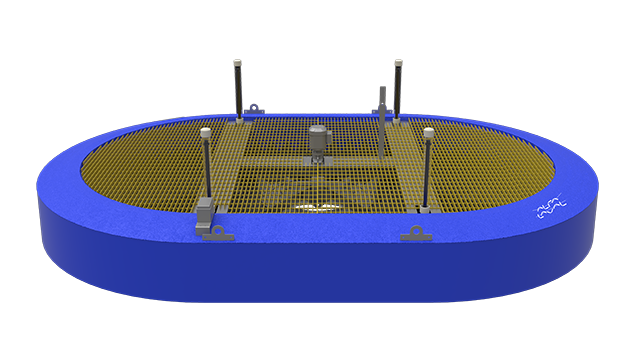

Il cuore del sistema è un decantatore flottante, una tecnologia di riferimento per la decantazione a portata costante, che garantisce la migliore qualità dell’effluente e ottimizza i processi a valle. La decantazione a portata costante dal livello acqua superiore a quello inferiore è ottenuta abbassando uno sfioratore circolare e/o periferico a “V”. Lo sfioratore viene fermato a una profondità tale da produrre la portata di decantazione target; una volta raggiunta, lo sfioratore si arresta in quella posizione e il principio del carico sopra sfioratore assicura il mantenimento di tale portata dal livello alto al livello basso.

Caratteristiche che fanno la differenza nel processo SBR di trattamento delle acque reflue

L’Alfa Laval ASH Floating Decanter utilizza uno sfioratore a V regolabile in profondità per decantare con precisione alla portata target, evitando il disturbo dei fanghi sedimentati e garantendo la migliore qualità possibile dell’effluente.

Il flusso di decantazione viene arrestato tramite un robusto meccanismo di azionamento che solleva lo sfioratore circolare a V sopra il livello dell’acqua, senza bisogno di speciali tenute o valvole sommerse.

Il collarino di galleggiamento in schiuma ad alta densità rivestita in vetroresina impedisce sia l’accumulo di solidi sia l’asportazione di schiume superficiali allo sfioratore.

Il sistema SBR Alfa Laval è controllato da un sistema di regolazione proporzionale alla portata che monitora continuamente il flusso in ingresso al reattore (o ai reattori) SBR, assicurando un tempo di trattamento ottimale per ogni fase del processo.

Poiché non è richiesta alcuna valvola motorizzata di decantazione dell’effluente, l’installazione risulta più semplice e meno complessa. Il decantatore flottante può inoltre essere acquistato come prodotto stand‑alone per gestire la decantazione in diversi bacini e lagune, inclusi i digestori aerobici.

Case history con soluzioni SBR per il trattamento delle acque reflue

Come possiamo aiutarti

Una delle grandi forze di Alfa Laval è la nostra competenza di processo: siamo a un clic di distanza per offrirti supporto operativo sul tuo processo a fanghi attivi.