Just as all plate heat exchangers are not created equal, neither are the replacement parts. Using lower cost, lower quality plates and gaskets can lead to decreased performance and increased costs.

Genuine rubber gaskets ensure tighter seals, longer lifetime and more uptime for gasketed plate heat exchangers. Alfa Laval gaskets may contain up to 30% more polymer than other gaskets, which contributes to optimal sealing.

Non-genuine gaskets may use the same nominal designations as genuine Alfa Laval gaskets, but their material properties differ.

Don't be fooled by gaskets that are slightly thicker - thicker is not better. Incorrect thickness causes inaccurate tightening calculations, which may cause leakage and/or deformation and destruction of the complete plate pack. This has been experienced by customers who use non-OEM spare parts.

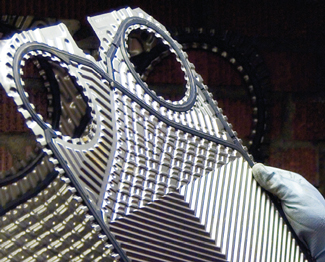

Genuine Alfa Laval plates are made using single-step pressing. This ensures uniform plate strength and thickness over the entire plate, dramatically reducing the risk of fatigue cracking.

The correct material quality can make a huge difference to a process. Alfa Laval ensures that the correct material is specified according to its intended use.

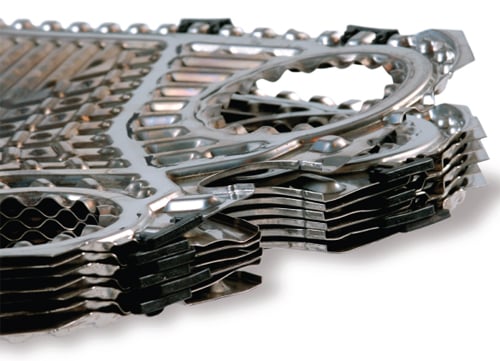

In addition to supplying spare parts individually, we also offer complete spare plate packs.

Plate packs often replace the most affected part of a plate heat exchanger.

By installing a new plate pack, the heat exchanger function is restored without having to replace the entire heat exchanger.

In order to show you how inefficient some suppliers parts can be, we conducted an investigation to see what would happen if an original plate in an Alfa Laval plate heat exchanger is replaced by three other parts suppliers' plates. The investigation was conducted by an accredited laboratory and consisted of a visual examination, stereo microscope evaluation, photographic documentation and measurement of pressing depths.

In summary, discrepancies were identified in eight major areas of the other suppliers' plates that can cause severe performance issues:

Click here to download the report

Exclusive stock for piece of mind

360° Service Portfolio brochure