LKHex

The Alfa Laval LKHex Centrifugal Pump is a premium pump for use in hygienic applications which must meet the requirements of the ATEX directive 2014/34/EU group II, category 2G, temperature class T3 and T4. To increase process productivity, it is distinguished by high efficiency, gentle product treatment, chemical resistance, and a wide range of flow rates, pressures and options.

Premium ATEX pump engineered for use in potentially explosive environments

- Energy efficient: superior efficiency resulting in reduced energy consumption and CO2 footprint.

- Hygienic: designed according to the most stringent hygienic design standards and with verified effective CIP cleanability.

- Maximized uptime and reduced maintenance costs: robust mechanical design and ease of maintenance with modular front-loading seals.

- Conforms to the provisions of ATEX directive: can be used in potentially explosive environments.

Precision-engineered, the ATEX pump LKHex delivers greater energy efficiency than similar pumps. Its optimized design, premium motor, tight tolerances and advanced impeller design minimize recirculation and reduce energy consumption. The LKHex is engineered for use in potentially explosive environments and conforms to the provisions of the ATEX directive 2014/34/EU group II, category 2G, temperature class T3 and T4. With verified effective CIP cleanability, it is ideal for hygienic applications within the dairy, food, beverage and personal care industries that require gentle product treatment and reliable operation. The Alfa Laval LKHex pump is available in 10 sizes to handle capacities up to 250 m3/h and differential pressures up to 11 bar at 50 Hz.

How does the LKHex centrifugal pump work?

Pump range

LKH centrifugal pumps are currently available in 13 sizes to handle capacities up to 500 m3/hour and pressures up to 190 H/(m). Options include types of shaft seals, flushing arrangements and elastomers.

LKHex for applications in explosive environments

Engineered for use in potentially explosive environments, the LKHex is available in nine sizes and conforms to the provisions of ATEX directive 94/9/EC Group II, Categories 2 and 3.

Unique impeller design

The semi-open impeller with a special vane design ensures particularly low NPSHr (Net Positive Suction Head required), making it ideal for ATEX equipment used in hazardous environments. This helps prevent cavitation and minimizes the risk of mechanical damage.

Balance holes in the impeller enhance circulation around the shaft seal and reduce axial forces. This minimizes wear on the shaft seal and motor bearings.

External shaft seal

The front-loading shaft seal, with the spring and washers mounted on the atmospheric side, makes maintenance fast, easy and inexpensive. It takes just a few minutes to replace the shaft seal. In addition, the balanced design minimizes the risk of seal opening during unforeseen pressure shock.

Optimised shaft seal

One shaft seal fits a wide pump range. The exact same LKH single shaft seal fits 11 models of LKH pumps as well as all models of the SolidC pump. The LKH seal also has the option of single or double flushed, which can be interchanged in minutes with just a few extra components.

This standardization reduces inventory and makes wear parts replacement quick and easy.

Compression couplings

Another notable feature is the compression coupling. This securely attaches the stub shaft to the motor shaft with precision alignment. Setup is simple, operations secure and noise and vibration minimized. What’s more, the coupling helps prolong the service life of both shaft seal and motor.

Catalogo Close at Hand

Il catalogo dei prodotti per dispositivi igienici "Close at hand" comprende schede prodotto, collegamenti ad animazioni, brochure e listini a scopo di ordinazione.

Portale CAD

Il portale CAD Alfa Laval è una piattaforma essenziale per scaricare informazioni dettagliate sui prodotti, disegni 2D e modelli di prodotti 3D.

Servizi di Assistenza

Il nostro servizio dedicato Global Service Network fornisce ricambi e assistenza tecnica specializzata ovunque e in qualsiasi momento. Assicurando maggiori livelli di operatività, disponibilità e ottimizzazione, offriamo al cliente tutta la tranquillità necessaria e un elevato ritorno sull'investimento. Possiamo collaborare per integrare i nostri servizi in un Contratto per i servizi di assistenza Alfa Laval per garantire un'operatività regolare e senza problemi.

Scopri di più sulla nostra offerta di servizi Risoluzione Problemi

Parti di ricambio Supporto tecnico

Ricerca numero seriale Certificazione

Contattaci per eventuali richieste o domande.

A premium performer

As Alfa Laval’s premium range of centrifugal pumps, the LKH centrifugal pumps are distinguished by high efficiency, low energy consumption, several options, and a wide range of flow rates and pressures.

High efficiency

A precision-engineered pump and motor provide high efficiency and gentle product treatment. The robust design and tight tolerances together with the advanced impeller design minimize recirculation and ensure the efficient transfer of energy.

Optimal pump design

The impeller design ensures efficient and gentle handling of the product as it moves through the pump. This ensures product integrity and minimizes NPSHr ( Net Positive Suction Head required).

Low energy consumption

Making pump energy use more efficient presents huge potential for energy savings. The optimized pump design and premium motor of Alfa Laval LKH centrifugal pumps often deliver greater energy efficiency than similar premium pumps and up to 50% compared to similar mid-range pumps.

Cleanability and hygienic design

The key is the attention to detail. Controlled compression gaskets, crevice free internals, an external mechanical seal, and an optimised impeller with balancing holes all ensure that the pump is truly cleaned during a time effective CIP cycle. Perfectly aligned components and joints with O-rings tightened to a predefined compression minimize the elastomer product contact surfaces, which also safeguards hygiene.

External shaft seal – hygienic and serviceable

By positioning the shaft seal outside the pump, difficult-to-clean components do not come into direct contact with the product. In addition, the front-loading design enables quick and easy replacement, providing more uptime with lower maintenance costs. Interchangeable single, flushed and double seals simplify spare parts inventory.

Warranty

Alfa Laval provides a three-year warranty for all non-wearing parts, provided genuine parts are used.

Visita l'Application & Innovation Centre

Vuoi identificare l'attrezzatura ottimale per il lavoro e scoprire risparmi tangibili prima di decidere di aggiornarla? Nell'Alfa Laval Application & Innovation Centre è possibile fare proprio questo.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval potenzia i tuoi processi esistenti e ti consente di risparmiare fino al 90% di acqua, energia e sostanze chimiche con investimenti ridotti e senza rischi.

Video di assistenza e manutenzione a 360 °

Alfa Laval LKH centrifugal pumps – change flushed shaft seal

Alfa Laval LKH centrifugal pumps double mechanical shaft seal

Alfa Laval Service Kits

Alfa Laval LKH centrifugal pumps – change single shaft seal

Part of a broad pump range

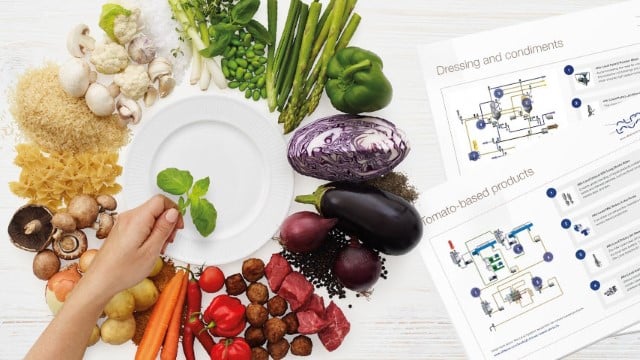

Alfa Laval offers a comprehensive range of pumps intended for hygienic applications in the dairy, food, beverage, home care and personal care.

Logica alimentare

I dispositivi igienici di Alfa Laval abbinano elevate prestazioni con una delicata manipolazione per non deteriorare gli ingredienti sensibili e restare al passo con le tendenze del settore alimentare. Affrontano quattro sfide chiave; fornitura di prodotti alimentari ai consumatori ad un prezzo competitivo, ottenendo il massimo dalle materie prime, riducendo gli sprechi e le emissioni e offrendo prodotti alimentari sicuri e igienici.

Iscriviti alla newsletter Near

Rimani aggiornato sulle principali problematiche e opportunità legate alla sostenibilità nel tuo settore e nei tuoi processi!

Animazioni

Visita il sito delle animazioni e accedi a un prodotto per vedere e capire come funziona.

Pensando al futuro, articoli tecnici

Pensare al futuro - Articoli tecnici e white paper sulle attrezzature igieniche